-

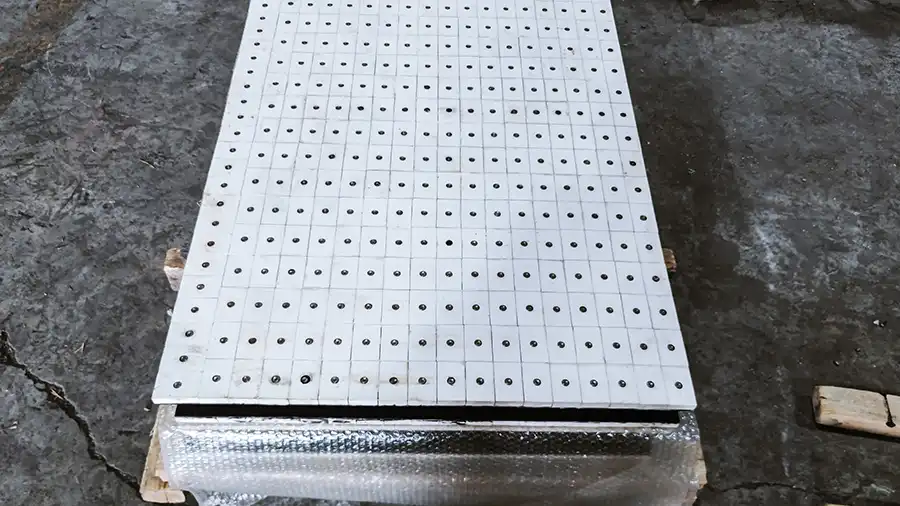

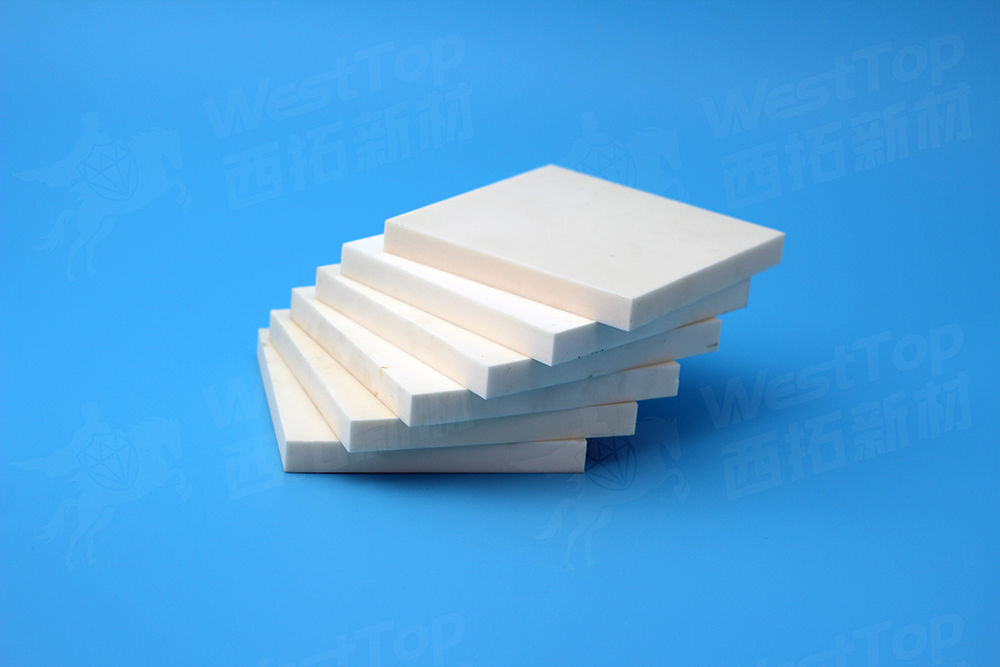

Sitomat Ceramic Wear-Resistant Liners – High-Performance Industrial Wear Protection

Sitomat ceramic wear-resistant liners are manufactured by processing premium wear-resistant ceramics through cutting, dovetail installation, adhesive bonding, and stud welding techniques. These processes result in various types of durable wear liners designed for industrial anti-wear applications. They are widely used in multiple types of industrial equipment, including: Material Options for Ceramic Wear Liners Depending on…

-

Application of silicon carbide wear-resistant ceramics in the inner cylinder of preheater

In the cement production line, the preheater inner cylinder is the core equipment component, and its technical performance is directly related to the production efficiency, energy consumption index and product quality stability. The traditional heat-resistant cast steel material and suspended flexible connection scheme have been verified by long-term application, but under the continuous action of…

-

Application of wear-resistant ceramic coating in iron and steel enterprises

With the continuous progress of science and technology, the application of wear-resistant ceramic coatings in all walks of life is becoming more and more common. Among them, wear-resistant ceramic coatings have unique advantages and practical value in iron and steel enterprises. Wear-resistant ceramic coatings have excellent wear resistance Wear-resistant ceramic coating is usually used with…

-

What is wear-resistant ceramic repair agent ? its characteristics and benefits

The wear-resistant ceramic repair agent is usually composed of two parts : A component and B component. It has no effect when used separately. It needs to be mixed in a certain proportion, and the wear resistant ceramic repair agent is applied to the polished equipment. After curing for some time, the installation can be…

-

What is cemented carbide

What is cemented carbide As a kind of alloy material prepared by powder metallurgy process, cemented carbide is mainly composed of metal carbides and bonded metals. It is usually a common collocation of tungsten carbide and cobalt. Cemented carbide has high hardness, high wear resistance, good compressive strength and toughness, excellent corrosion resistance and heat…

-

Pressure pipeline element is one of the main components of industrial pipeline transportation system.

Pressure pipeline components are one of the main components of industrial pipeline transportation systems. They are a general term for pipeline-related components with internal pressure and are the key to the operation of pressure pipeline transportation systems. Metal pipes and related accessories The main body of the pipeline, the flange used for connection and the…

-

The core performance advantages and applications of wear-resistant ceramic materials

Ⅰ. Technical challenges of industrial equipment wear and tear In the industrial production system, the wear of equipment surface is a technical problem that restricts the development of industrial enterprises for a long time. The rapid loss of material surface not only leads to the decrease of equipment operation efficiency and the increase of maintenance…

-

Modern ceramic composite alumina armor

In the development process of military equipment technology, the innovation of material system has always been the core driving force to promote the improvement of equipment performance. In recent years, modern ceramic composite materials have realized large-scale application in the field of military protection by virtue of their unique physical and mechanical properties. They have…

-

Factors affecting the density of alumina ceramics

As an industrial wear-resistant material, alumina ceramics have wide application value in industrial fields such as iron and steel metallurgy, cement transportation, machinery manufacturing, new energy batteries and chemical equipment. It is often used as a wear-resistant lining and key structural components of engineering equipment due to its excellent high temperature stability, high wear resistance…

-

What is tortoise shell mesh wear-resistant ceramic coating, its performance characteristics ?

Wear-resistant ceramic coating for tortoise shell net is a kind of anti-wear material formed by applying wear-resistant and corrosion-resistant ceramic coating to hexagonal tortoise shell net made of special metal materials with high temperature resistance and corrosion resistance.After spot welding on the inner wall of the equipment, the refractory or wear-resistant material is filled. After…

Search

About

Sitomat is Global technical experts in the field of industrial wear prevention, focusing on the in-depth application research of wear-resistant ceramic pipes, ceramic liners and composite wear prevention systems. Collects 15 years of wear repair data from the mine/power/cement industry and serves the equipment life extension plan of 237 heavy industry enterprises around the world.

Provide full-scenario wear-resistant solutions for mining, power, cement, metallurgy and other industries

Archive

Categories

- Cement industry applications

- Ceramic liner

- Ceramic lining

- Ceramic particle repair agent

- Ceramic Pipe

- ceramic pipes

- Ceramic Sheet

- Ceramic Sheet

- Ceramic valves

- Coal industry applications

- Composite liner

- Industry Information

- Metal wear-resistant products

- News

- products

- Steel industry applications

- Thermal power industry

- Wear-resistant equipment

Recent Posts

- Sitomat Ceramic Wear-Resistant Liners – High-Performance Industrial Wear Protection

- Application of silicon carbide wear-resistant ceramics in the inner cylinder of preheater

- Application of wear-resistant ceramic coating in iron and steel enterprises

- What is wear-resistant ceramic repair agent ? its characteristics and benefits

- What is cemented carbide

Gallery