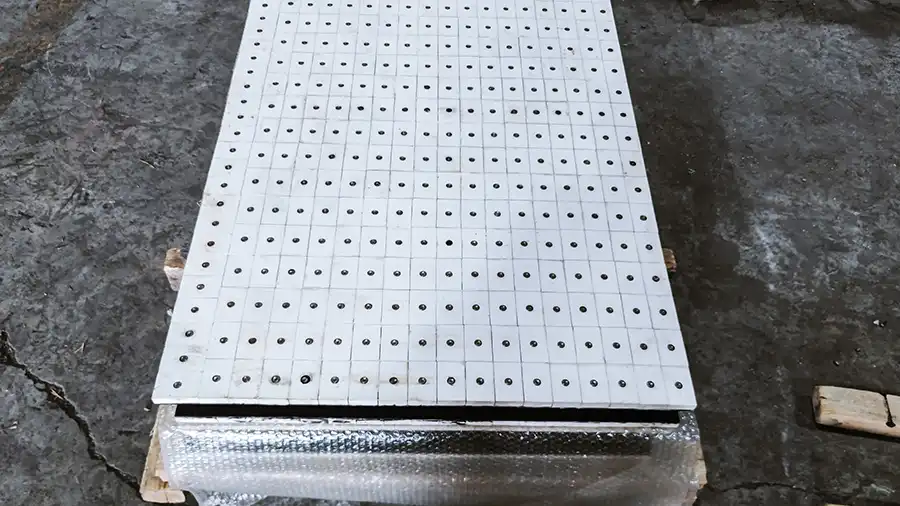

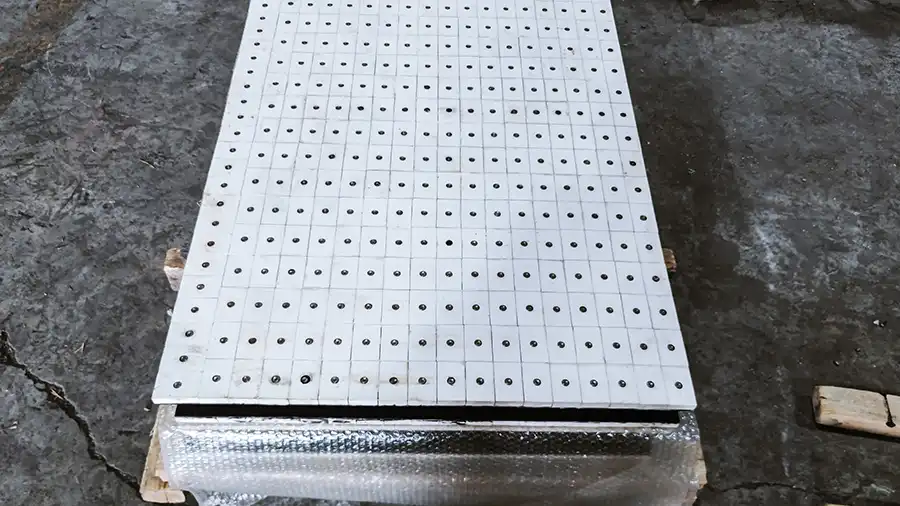

Sitomat ceramic wear-resistant liners are manufactured by processing premium wear-resistant ceramics through cutting, dovetail installation, adhesive bonding, and stud welding techniques. These processes result in various types of durable wear liners designed for industrial anti-wear applications.

They are widely used in multiple types of industrial equipment, including:

- Pulverized coal pipelines

- Powder separators

- Cyclone separators

- Grate coolers

- Fan impellers

- Coal burners

- Chute hoppers, and more.

Material Options for Ceramic Wear Liners

Depending on specific operational requirements, different ceramic materials can be selected, such as:

- Alumina ceramic (Al₂O₃) – excellent hardness and cost-effectiveness

- Zirconia ceramic (ZrO₂) – superior toughness and wear resistance

- Alloy ceramics – enhanced composite properties

For adhesive bonding, both low-temperature adhesives and high-temperature adhesives are available.

Temperature Resistance:

Bonded ceramic wear-resistant liners are typically suitable for environments up to 300°C.

Welded ceramic liners and dovetail ceramic liners can withstand 300°C to 800°C, making them ideal for high-temperature applications.

Common Thickness Specifications: 5mm, 7mm, 10mm, 15mm, 20mm, and 30mm.

Key Performance Features

- Exceptional Wear Resistance

- Extends equipment service life by 10 times or more compared to standard protection materials.

- Excellent Stability & Toughness

- Secure installation with high impact resistance to handle heavy-duty industrial conditions.

- High-Temperature Durability & Non-Shedding

- Performs reliably in high-heat environments without detachment issues.

Wide Range of Applications

Customizable based on material choice, making it suitable for a broad spectrum of industrial equipment with diverse functions.

Why Choose Sitomat Ceramic Wear Liners?

Sitomat’s ceramic wear liners combine cutting-edge manufacturing technology with superior materials to deliver maximum equipment protection in harsh industrial environments. Whether for coal handling systems, cement plants, steel mills, or mining operations, these liners significantly reduce downtime, maintenance costs, and operational risks.

📩 Contact us today to get a tailored ceramic wear liner solution for your equipment.