In the development process of military equipment technology, the innovation of material system has always been the core driving force to promote the improvement of equipment performance. In recent years, modern ceramic composite materials have realized large-scale application in the field of military protection by virtue of their unique physical and mechanical properties. They have gradually replaced traditional metal materials and become key materials for non-load-bearing armored components in combat platforms and individual protective equipment, which has brought new changes to the development of military protection technology.

In many ceramic-based bulletproof material systems, in addition to the widely used silicon carbide ceramic bulletproof board, the alumina ceramic bulletproof board developed by Sitomat Ceramics also shows important engineering application value. With its excellent comprehensive performance, this material has built a unique technical advantage in the field of bulletproof, and has become an important part of the current lightweight armored material system.

1.The core performance advantages of alumina ceramics

Alumina ceramics have significant physical and mechanical properties, and its primary advantage is reflected in its excellent anti-penetration ability. The material itself has extremely high hardness ( Mohs hardness ≥ 9 ) and compressive strength ( ≥ 3000MPa ). Under the impact load of high-speed projectiles, the kinetic energy of the projectile can be transformed into the fracture energy of the material through the micro-crack propagation and crushing energy absorption mechanism of the surface material. The specific process is as follows : When the projectile core impacts the ceramic surface at a supersonic speed ( 800-1200m / s ), a dense crushing cone is quickly formed on the surface of the material. Through the friction slip between the grains and the crack network expansion, the deformation passivation or structural fracture of the projectile core occurs, thereby effectively dissipating the kinetic energy of the projectile body and protecting the subsequent bearing structure.

The material also has excellent environmental adaptability, and its wear resistance is 3-5 times higher than that of traditional metal materials. In complex environments such as dust and salt fog, the surface wear rate is low. In terms of chemical stability, the corrosion rate of the material in the acid and alkali environment is small, which can meet the reliability requirements of long-term outdoor service. It is particularly important that the density of alumina ceramics is only 3.6-3.9g / cm3, which is significantly lower than that of steel materials ( 7.85g / cm3 ), and the weight is reduced by 40 % -50 % under the same protective area. This feature has key tactical value for improving the mobility of individual equipment, which can reduce the weight of combatants by 20 % -30 %, and effectively improve the battlefield mobility.

2.Technical characteristics of ceramic alumina bulletproof vest board

The alumina armor developed by Sitomat Ceramics adopts advanced nano-composite sintering process to form a microstructure with multi-scale grain synergistic enhancement, which has the following core technical characteristics :

High-efficiency energy absorption mechanism : By optimizing the material composition ( Al 2O 3 purity ≥ 95 % ) and microstructure design, the specific energy absorption value of the material can reach 80-100J / g, which can effectively resist typical threats such as 9mm Para pistol bullet ( initial velocity 360m / s ) and 7.62 × 51mm rifle bullet ( initial velocity 850m / s ). The back deformation depth is controlled within 12mm, which meets the NIJ III protection standard.

Lightweight structure design : The thickness distribution of the bulletproof plate is optimized by finite element simulation. Under the premise of maintaining the equivalent protection ability, the weight per unit area is controlled at 8-10kg / m2, which is more than 60 % lighter than the traditional steel armor, and the optimization balance between high specific strength and lightweight design is realized.

Long-term service stability : The creep resistance of the material is excellent. When it is subjected to 100 MPa stress at 60 °C, the creep strain of 1000 hours is less than 0.1 %. The gradient interface structure design is adopted to effectively suppress the interface debonding problem under long-term alternating load. After 500 simulated actual impact tests, the material strength retention rate is ≥ 95 %.

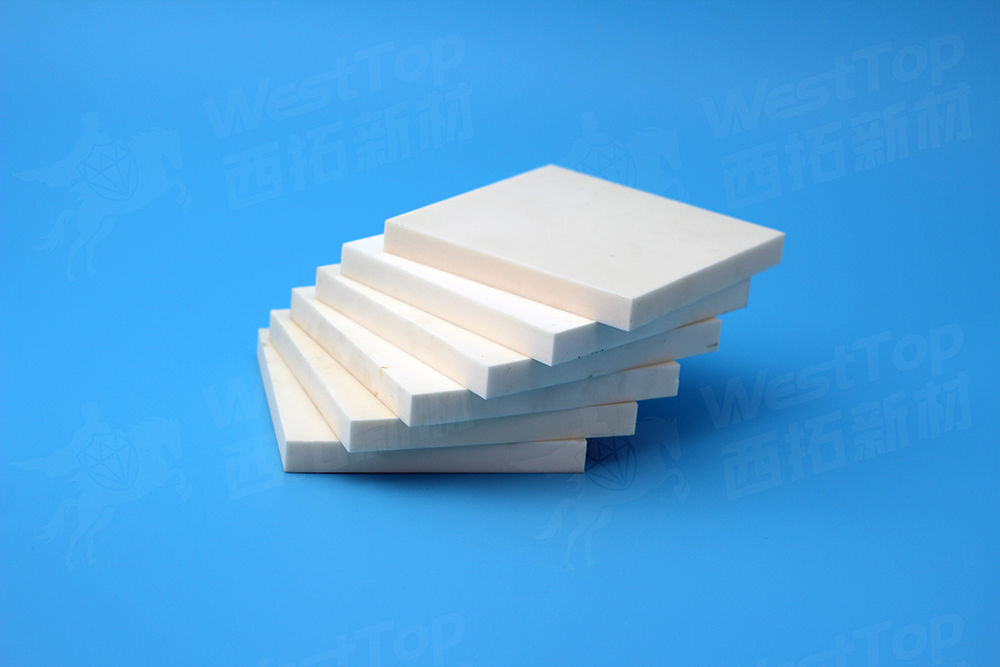

3.Engineering adaptability of product configuration

This series of bulletproof panels provide diversified geometric configuration solutions. The standard products include conventional shapes such as 100mm × 100mm square, 250mm × 300mm rectangle, equilateral triangle ( side length 150mm ) and regular hexagon ( opposite side distance 200mm ). The thickness range is 5-20mm, which can meetthe modular assembly requirements of different protective parts. Aiming at the personalized protection requirements of special equipment, Sitomat Ceramics provides customized design services. Through 3D scanning modeling and CNC machining technology, the precise preparation of complex surface configurations ( such as arcs, trapezoids, etc. ) is realized, and the dimensional accuracy is controlled within ± 0.1mm. It provides a flexible engineering solution for the integrated protection design of high-end military equipment.

4.Application prospect and technology prospect

With the development trend of lightweight and high mobility of military equipment, the application of ceramic matrix composites in the field of armor protection will continue to deepen. Alumina ceramics have become the preferred material for current low-end protection scenarios ( individual chest armor, vehicle additional armor, etc. ) due to their balanced advantages in cost, process maturity and comprehensive performance. In the future, with the development of nanocomposite technology, gradient functional material design and additive manufacturing technology, the material system will achieve technological breakthroughs in the following directions : First, the introduction of ZrO2 phase transformation toughening, carbon nanotube conductive enhancement and other technologies to improve the material ‘s elastic toughness and electromagnetic compatibility ; the second is to develop a multi-layer composite structure design to achieve efficient protection against multiple threats such as kinetic energy projectiles and fragments ; the third is to promote the composite application of aramid fiber, ultra-high molecular weight polyethylene and other fiber materials, and build a rigid-flexible coupling lightweight protection system.

In summary, as a typical representative of modern ceramic composite materials, the technical advantages of alumina ceramic bulletproof materials meet the core requirements of lightweight and high reliability in the field of military protection. With the continuous progress of material preparation technology, this material will play a more critical role in the future battlefield protection system, and provide solid material and technical support for the improvement of equipment survivability and personnel safety protection.

One response to “Modern ceramic composite alumina armor”

[…] Structural ceramics : With bearing, wear resistance and high temperature resistance as the core functions, it is mainly used for mechanical structural parts ( such as ceramic bearings ), industrial protective parts ( such as wear-resistant lining plates ), high temperature structural parts ( such as furnace tubes ), etc., emphasizing the mechanical properties and structural stability of materials. […]