In today’s industrial conveying systems, ensuring reliable and safe pipeline operation under high pressure, abrasive, and corrosive conditions is critical. The Sitomat BWP bimetal wear-resistant pipe was designed to solve these challenges. With advanced manufacturing technology and superior material properties, it has become a trusted solution for industries such as metallurgy, cement, power generation, mining, and coal.

Advanced Structure & Manufacturing Process

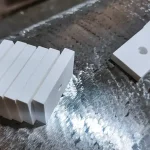

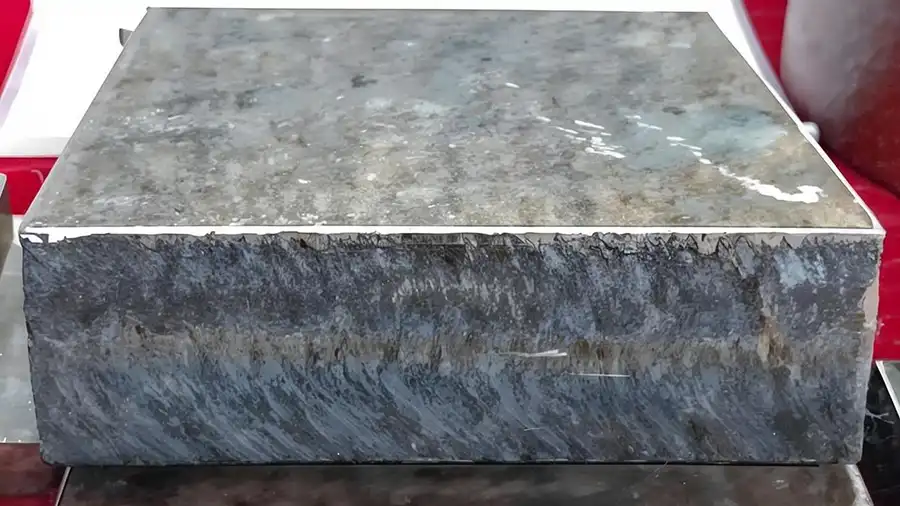

The BWP bimetal pipe is built with a seamless steel outer wall and a high-chromium-nickel alloy inner lining. Using centrifugal casting or vacuum negative pressure casting, the two layers form a strong metallurgical bond. This design combines the strength and pressure-bearing capacity of steel with the wear and corrosion resistance of alloy, delivering long-lasting durability.

Core Advantages

- High Pressure Capacity: The seamless steel shell ensures safety under demanding high-pressure and long-distance transport conditions.

- Superior Wear Resistance: With a hardness rating of HRC55–60, the alloy lining offers 20–30 times the wear resistance of standard steel pipes and 5–10 times that of cast wear-resistant pipes.

- Impact Resistance & Easy Maintenance: The pipe can be hammered, cut, welded, and reinstalled when needed, allowing quick and flexible maintenance.

- High-Temperature Endurance: Performs reliably at temperatures up to 600℃ without deformation or oxidation, maintaining excellent wear resistance in extreme environments.

- Strong Corrosion Resistance: Effectively withstands sulfuric acid, hydrochloric acid, hydrofluoric acid, and caustic solutions under 5%, making it ideal for corrosive media.

- Anti-Scaling Inner Wall: Advanced casting methods create a smooth inner lining that prevents buildup and improves flow efficiency.

- Simplified Installation: Supports welding, flanging, and other standard connection methods, offering flexibility across different engineering setups.

Industry Applications

- Metallurgy: Slag transport systems

- Mining: Slurry pipelines and dry material handling

- Power Generation: Ash and slag conveying systems

- Coal & Chemical Processing: Mine backfilling and dense slurry transport

Cost-Performance Advantage

While ceramic wear-resistant pipes typically offer longer service life, the Sitomat BWP bimetal pipe provides a more affordable solution for less extreme environments. Its combination of durability and lower upfront investment makes it a cost-effective choice for many industries.