Alumina Ceramic (Al2O3) is one of the most widely used categories in advanced ceramic material systems. Relying on its excellent comprehensive physical and chemical properties, it has been widely used in many key fields such as industrial manufacturing, electronic information, medical equipment, national defense and military industry.

In modern industrial production scenarios, this material has become an ideal technical solution to cope with complex engineering conditions and meet the needs of high-end materials due to its core advantages such as high hardness, strong wear resistance, excellent high temperature resistance and stable electrical insulation.

The classification system of alumina ceramics (Al2O3)

According to the differences in material purity, preparation process and functional positioning, alumina ceramics can be divided into the following main categories :

Classification by purity

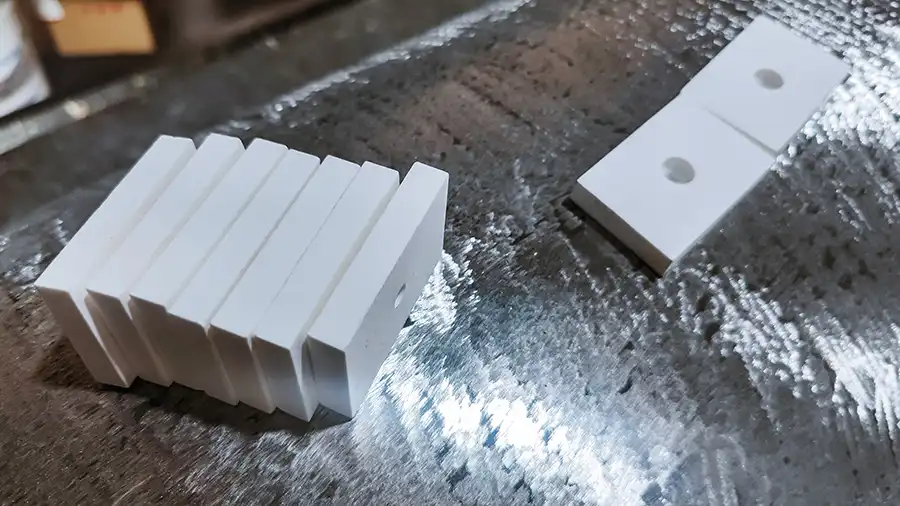

95 % alumina ceramic : the content of Al2O3 is about 95 %, and the other components are sintering aids such as silicon dioxide and magnesium oxide. This category has a low preparation cost and a significant cost-effective advantage. It is mainly used for wear-resistant parts ( such as bearing rings ) and ordinary electrical insulation parts ( such as insulators ) in general industrial scenarios to meet the needs of low-end industries.

99 % alumina ceramics : Al2O3 was increased to more than 99 %, and the impurity content was greatly reduced. The mechanical strength, electrical insulation and high temperature resistance of 99 % alumina ceramics were significantly improved compared with 95 % alumina ceramics. This category is mainly used in high-end electronic ceramic substrates ( such as power semiconductor substrates ), precision seals ( such as vacuum equipment sealing rings ) and other scenes with high performance requirements.

Classification by function orientation

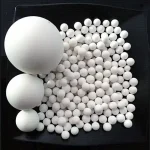

Structural ceramics : With bearing, wear resistance and high temperature resistance as the core functions, it is mainly used for mechanical structural parts ( such as ceramic bearings ), industrial protective parts ( such as wear-resistant lining plates ), high temperature structural parts ( such as furnace tubes ), etc., emphasizing the mechanical properties and structural stability of materials.

Functional ceramics : With electrical, optical, biological and other special functions as the core, it is mainly used in electronic components ( such as insulating substrate ), optical devices ( such as transparent ceramics ), medical devices ( such as artificial joints ), etc., emphasizing the functional characteristics and precise control of materials.