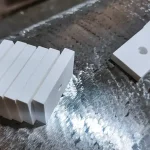

In modern industrial applications, the choice of wear-resistant materials directly determines equipment lifespan and production efficiency. Sitomat silicon carbide wear-resistant ceramic plates (RSIC/SISIC) are widely recognized for their outstanding hardness, wear resistance, and corrosion resistance, making them the preferred lining materials in mining, steel, coal processing, chemical, and raw material manufacturing industries.

What is Reaction Sintered Silicon Carbide (RSIC/SISIC)?

Reaction sintered silicon carbide (RSIC/SISIC) is a high-performance ceramic produced through a high-temperature reaction sintering process. Compared to traditional wear-resistant ceramics, SISIC features higher density and extremely low porosity, resulting in superior hardness, excellent wear resistance, and strong impact strength.

Advantages of Sitomat Silicon Carbide Ceramics

- Exceptional hardness and wear resistance – Significantly extends equipment service life and reduces downtime.

- Excellent impact resistance – Ideal for conveying coarse particles and highly abrasive materials.

- Corrosion resistance – Withstands various acids and alkalis, ensuring durability in chemical environments.

- High-temperature resistance – With a maximum operating temperature up to 1350℃, it is suitable for demanding thermal applications.

- Outstanding thermal stability – High thermal conductivity and low thermal expansion ensure excellent thermal shock resistance at 1200℃.

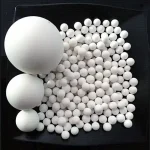

- Versatile shapes and sizes – Available in square, rectangular, hexagonal, and circular designs, and can be customized for specific operating conditions.

Main Parameters of Silicon Carbide Ceramics

Physical Properties

- Thermal Conductivity: ~120–200 W/m·K (much higher than alumina at ~30 W/m·K)

- Thermal Expansion Coefficient: 4.0–4.5 × 10⁻⁶/K, with minimal dimensional change

- Density: Bulk density ≥ 3.04 g/cm³

- Hardness: Mohs hardness 9.2–9.5 (second only to diamond and cubic boron nitride)

- Elastic Modulus: ~400–450 GPa, providing strong structural stability

Mechanical Properties

- Compressive Strength: RSIC > 2200 MPa

- Flexural Strength: 400–600 MPa at 25°C (self-bonded SiC)

- High-Temperature Strength: Self-bonded SiC maintains 250 MPa at 1410°C

Chemical Properties

- Corrosion Resistance: Excellent resistance to sulfuric acid, hydrochloric acid, nitric acid, alkalis, and molten metals (aluminum, copper).

- Oxidation Resistance: A SiO₂ passivation layer forms at high temperatures, enabling long-term use in air at 1600°C.

Process Parameters

- Sintering Temperature: 1450–1750°C (RSIC in vacuum), 1450–1600°C (self-bonded SiC)

- Operating Temperature: Over 1600°C in inert/weakly oxidizing atmospheres; up to 1400°C in long-term air exposure

Special Application Parameters

- Thermal Shock Resistance: Withstands ΔT > 1000°C without cracking

- Wear Resistance: Excellent abrasive wear resistance, ideal for high-wear environments

Application Fields

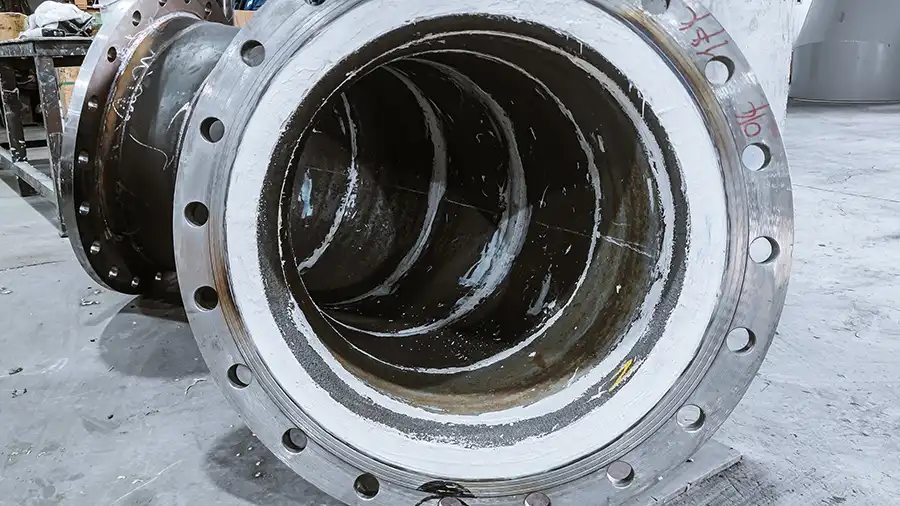

- Mining Industry – Ore pipelines, cyclone separators, chutes, and hoppers

- Steel Industry – Furnaces, bins, and classification equipment

- Coal Processing – Classification, dewatering, and concentration equipment

- Chemical & Raw Material Manufacturing – Reactors, pipes, and corrosion-resistant equipment

- Mechanical Seals & Sandblasting – Enhances durability in abrasive environments

- Optical & Reflector Applications – Suitable for specialized industrial reflectors

Sitomat Composite Products

For even greater performance under heavy impact and abrasive conditions, Sitomat also offers silicon carbide ceramic-rubber composite wear linings. These combine the extreme hardness of ceramics with the shock-absorbing properties of rubber, making them ideal for bulk material handling and high-impact applications.

Conclusion

If you are looking for a high-performance wear-resistant material for mining, steel, coal, or chemical applications, Sitomat silicon carbide ceramic plates are the perfect choice. With their outstanding wear resistance, high-temperature stability, and corrosion resistance, they reduce maintenance costs, extend equipment service life, and significantly improve production efficiency.