In the process of deep processing of ore and chemical raw materials, ball mill is an indispensable crushing equipment. After preliminary crushing, the material needs to be further ground into fine powder by ball mill to meet the needs of subsequent processing or application. According to different process methods, ball mills can be divided into two types : dry mill and wet mill ( water mill ).

The working principle of ball mill

The ball mill is mainly composed of cylinder, grinding medium and driving device. When the motor drives the cylinder to rotate, the grinding medium ( such as steel balls and ceramic balls ) in the cylinder will be taken to a certain height, and then fall freely due to gravity, impacting and grinding the material to achieve crushing.

In the dry ball mill, the material does not add water during the grinding process, which is suitable for industries with high requirements for powder dryness, such as cement, refractory, chemical and ceramic raw materials. The advantage of dry grinding is that it is convenient for classification and collection, and avoids chemical reactions caused by contact between materials and water.

In contrast, the wet grinding ball mill is to add a certain proportion of water or liquid during the grinding process, so that the material is suspended and rolled with the grinding medium. Wet grinding can effectively reduce dust and has higher grinding efficiency, which is suitable for materials with very high fineness requirements.

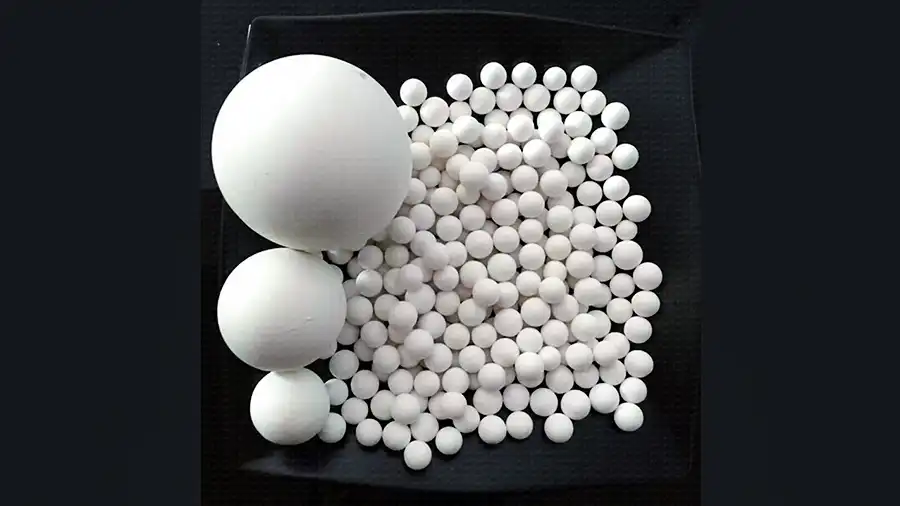

Alumina ceramic balls : high-performance grinding media

Among many grinding media, alumina ceramic ball is one of the most widely used at present. Its main features include :

- High hardness and wear resistance —— alumina ceramic balls have high Mohs hardness, which can maintain grinding efficiency for a long time and reduce dielectric loss.

- Good chemical stability —— It not easy to react with the material to ensure the purity of the product.

- Moderate density —— It can effectively improve the grinding efficiency and shorten the grinding cycle.

- widely used —— it is widely used in mineral processing, electronic ceramics, fine chemical, pharmaceutical and food industries.

Advantages of Sitomat Ceramics dry grinding balls

As a professional industrial ceramic manufacturer, Sitomat Ceramics focuses on the development and production of dry grinding balls. Its products have the following significant advantages :

- The particle size is uniform and the grinding effect is stable ;

- Long service life, reduce production costs ;

- Low energy consumption, improve the overall efficiency of ball mill ;

- Support multi-industry applications to meet the process needs of different customers.

Summary

Whether it is dry grinding or wet grinding, ball mill is an irreplaceable equipment in modern industrial grinding. The selection of appropriate grinding media, especially alumina ceramic balls, will directly affect the grinding efficiency and product quality. Sitomat Ceramics provides high-performance dry grinding ball solutions to bring a more stable and economical grinding experience to customers.