In the industrial domain, equipment wear and tear pose a substantial financial challenge. According to McKinsey’s research, industries worldwide allocate billions of dollars annually to address equipment wear – related issues. For example, a single mining facility may incur up to $2 million in annual expenses solely for equipment wear repairs. Such high costs not only erode corporate profits but also impede operational efficiency, presenting a significant hurdle for businesses.

Wear – resistant ceramic liners have emerged as an effective solution to combat industrial abrasion. Engineered to endure extreme conditions, these liners significantly reduce the frequency of repairs and replacements. By the conclusion of this article, readers will gain comprehensive knowledge on how to select, install, and optimize the return on investment (ROI) of ceramic liners.

What Are Wear – Resistant Ceramic Liners?

Wear – resistant ceramic liners are fabricated from high – purity alumina (Al₂O₃) ceramics, with purity levels ranging from 92% to 99%. The manufacturing process involves hot – pressing and sintering techniques, resulting in a modular design that facilitates versatile applications.

A comparative analysis of ceramic, steel, and rubber liners reveals the distinct advantages of ceramic liners:

| Liners | Weight | Hardness | Lifespan |

| Ceramic | 50% lighter than steel | Vickers hardness ≥1500 HV | Up to 10 times longer than manganese steel |

| Steel | Heavy | Lower hardness compared to ceramic | Shorter lifespan |

| Rubber | Light | Low hardness | Short lifespan |

Key performance metrics of ceramic liners include a Vickers hardness of at least 1500 HV and a density ranging from 3.6 – 3.9 g/cm³, underscoring their superior mechanical properties.

Benefits of Ceramic Liners

- Extended Service Life: Field test data demonstrates that ceramic liners outperform manganese steel by a factor of 10 in terms of lifespan, significantly reducing replacement frequencies.

- Reduced Structural Load: With a weight of 12kg per 1㎡, compared to 45kg for steel liners, ceramic liners alleviate the overall structural burden.

- Corrosion Resistance: Exhibiting zero corrosion in acidic and alkaline environments (pH 3 – 14), ceramic liners are suitable for a wide range of chemical – exposure applications.

- High – Temperature Tolerance: Capable of withstanding temperatures up to 800°C, ceramic liners maintain structural integrity in high – heat industrial processes.

- Energy Efficiency: A case study from a manufacturing plant reported a 15% reduction in energy consumption following the installation of ceramic liners, attributed to reduced frictional losses.

- Ease of Installation: The installation process, utilizing epoxy or inorganic adhesives, is streamlined and can be executed with minimal downtime.

- Customizability: Available in various shapes, including hexagonal, square, and interlocking designs, ceramic liners can be tailored to fit diverse equipment configurations.

- Regulatory Compliance: Compliant with FDA standards, ceramic liners are suitable for use in food and pharmaceutical industries, ensuring safety and regulatory adherence.

- Cost – Benefit Analysis: Utilize our interactive cost – savings calculator to estimate potential savings over a 5 – year period.

Industry Applications & Case Studies

Mining

In the mining sector, ceramic liners are widely applied in crushers, chutes, and hoppers. Rio Tinto, a leading mining corporation, reported a notable reduction in equipment wear following the installation of ceramic liners in their crushing equipment.

Cement

For cement plants, ceramic liners are installed in cyclones and kiln inlets. Comparative before – and – after wear analyses have demonstrated a significant decrease in wear and tear, leading to enhanced plant efficiency.

Power Generation

In power generation facilities, ceramic liners are utilized in coal pulverizers and ash – handling systems, effectively reducing maintenance costs and downtime.

Steel

In the steel industry, ceramic liners are employed in blast furnace components to withstand high temperatures and abrasive conditions.

Case Study: An mining company, achieved a 75% reduction in downtime after implementing sitomat Ceramic Liners.

How to Choose the Right Ceramic Liner?

Step 1: Requirements Assessment

Evaluate the abrasion level, operating temperature, and impact forces to which the equipment will be exposed.

Step 2: Thickness Selection

- 6mm thickness: Ideal for low – abrasion areas

- 10mm thickness: Suitable for medium – abrasion applications

- ≥15mm thickness: Recommended for high – abrasion environments

Step 3: Surface Design

Select from flat, ribbed, or dimpled patterns based on specific operational re

quirements.

Step 4: Adhesive Selection

- Epoxy adhesive: Recommended for temperatures below 120°C

- Inorganic adhesive: Suitable for temperatures above 200°C

Caution: Be vigilant against low – quality imitations with Al₂O₃ content below 90%.

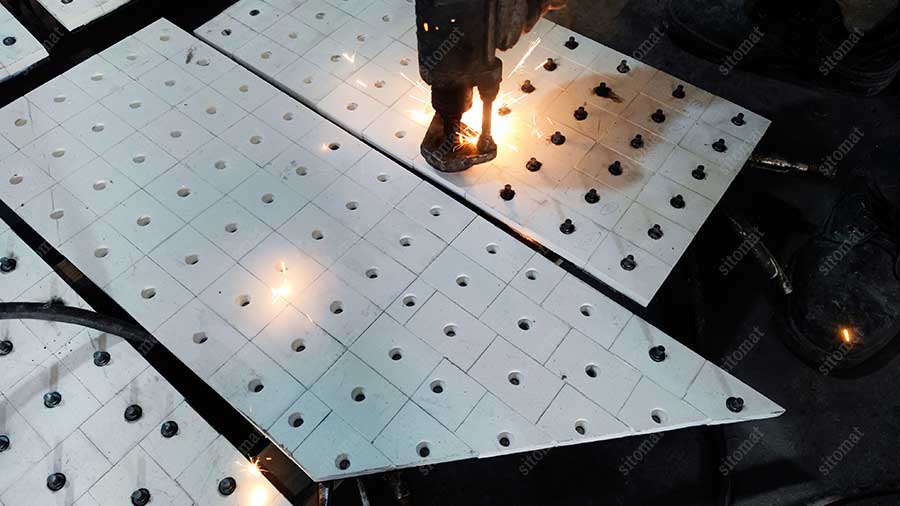

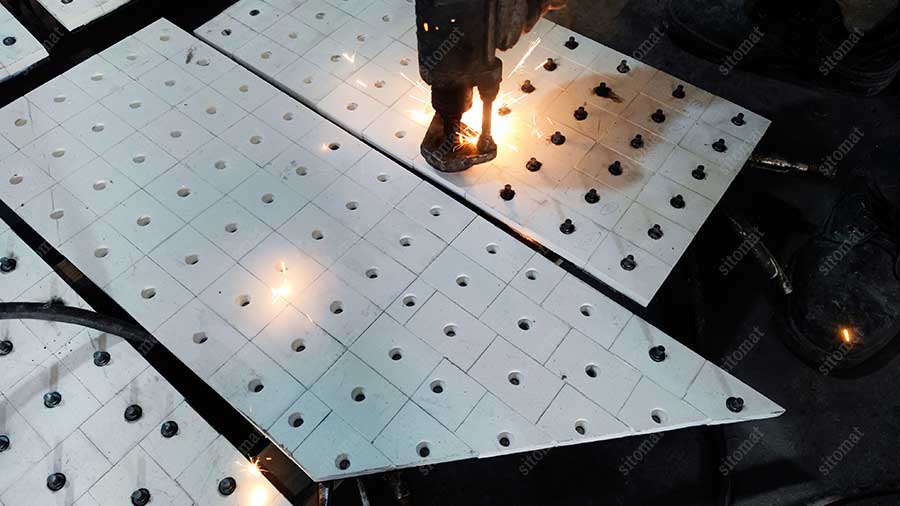

Installation & Maintenance Best Practices

5 – Step Installation Guide

- Surface Preparation: Clean and roughen the substrate surface to ensure optimal adhesion.

- Adhesive Application: Apply the selected adhesive uniformly across the surface.

- Liner Placement: Carefully position the ceramic liners on the adhesive – coated surface.

- Alignment and Fixing: Ensure proper alignment and secure the liners using appropriate fastening methods.

- Curing: Allow the adhesive to cure according to the manufacturer’s specifications.

Installation Guidelines

- Do: Use torque wrenches for bolt tightening to prevent liner damage.

- Don’t: Avoid welding in the vicinity of installed liners to prevent thermal stress – induced damage.

Maintenance Protocol

- Conduct semi – annual inspections for cracks or loose tiles.

- Utilize repair kits for minor damages to extend the liner’s service life.

FAQs:

Can ceramic liners withstand heavy impacts?

Yes. Test results in accordance with ASTM C179 standards confirm that ceramic liners can effectively withstand significant impact forces.

How long do ceramic liners last?

Depending on the application, ceramic liners can have a service life ranging from above 3 years.

Are they safe in high temperature environment?

Yes, The wear-resistant ceramic lining can withstand high temperatures of over 800 degrees Celsius and can be used normally in high temperature environments

Can I retrofit ceramic liners to old equipment?

Yes, ceramic liners exhibit approximately 90% compatibility with retrofitting applications.

Why Choose Us?

- Certifications: Our products adhere to ISO 9001 (Quality Management System), ISO 14001 (Environmental Management System),ensuring superior quality.

- Global Partnerships: Collaborations with numerous Fortune 500 companies attest to our reliability and product excellence.

- Research and Development: Our patented anti – spalling technology showcases our commitment to continuous innovation and technological advancement.

contact us

- Request a Custom Solution tailored to your specific requirements.