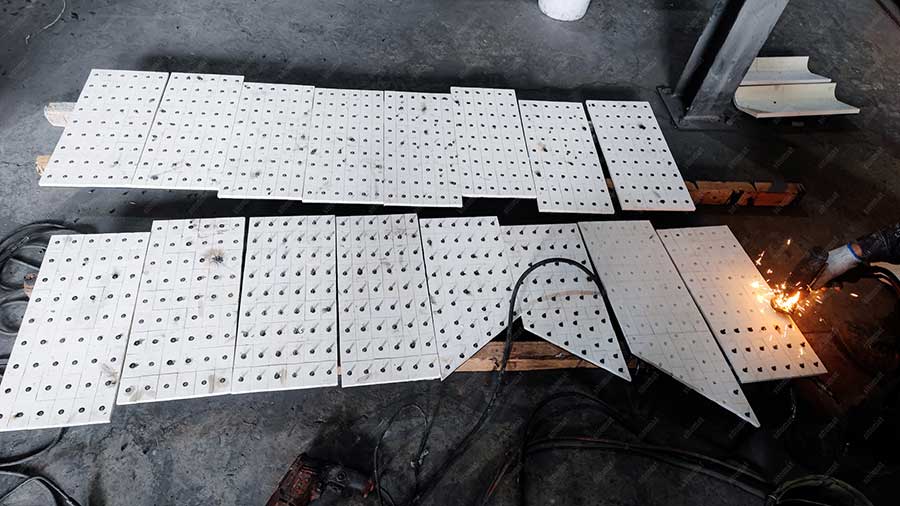

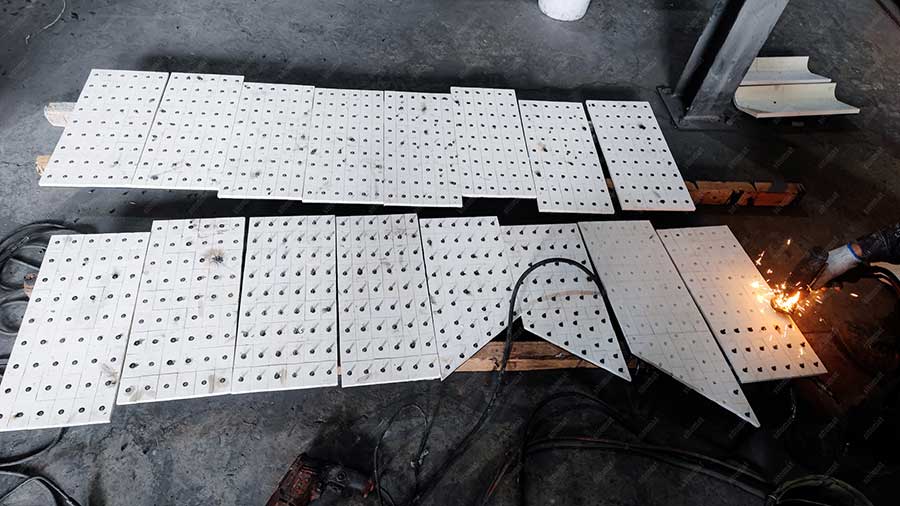

The wear-resistant ceramic liner board is a special wear-resistant ceramic, which is made of AL2O3 as the main raw material, rare metal oxide as the flux, and fired at 1700 degrees Celsius. Wear-resistant ceramic liner has excellent performance characteristics such as high temperature resistance, corrosion resistance and wear resistance. It is widely used in anti-wear of mechanical equipment, steel plant, thermal power plant, cement plant and other system equipment or pipeline anti-wear. Below, we will understand the application of wear-resistant lining board in iron and steel plants.

- Material conveying system : trolley three-way hopper, coke hopper, stacker-reclaimer hopper, zipper feeder tank, ore transfer hopper ;

- Sintering conveying system : batching bin, ore dressing hopper under vibrating screen, long-distance ore dressing hopper, cylinder mixer, cylinder granulator liner ;

- Pneumatic conveying system : fan impeller, fan shell, wear-resistant circular air door, expansion joint ;

- Dust collecting system : sintering machine dust collecting duct, dust collecting duct, cyclone dust collecting duct, distributor ;

- The above is the application of wear-resistant lining plate in steel plant.