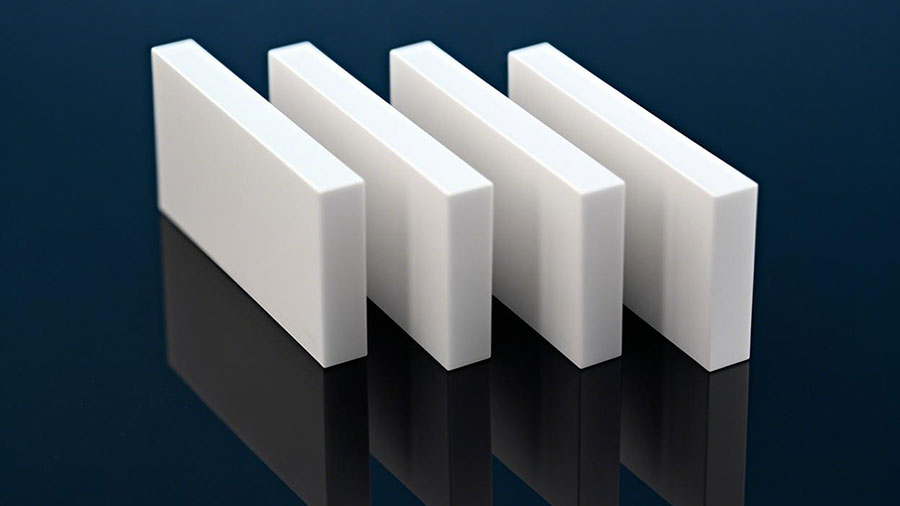

In the field of industrial materials science, alumina wear-resistant ceramic sheet has become a key engineering material due to its excellent comprehensive properties.

1.The main components of alumina wear-resistant ceramic sheet

The main component of alumina wear-resistant ceramic sheet is alumina ( Al2O3 ). According to the actual engineering application requirements and performance index requirements, the alumina content is usually controlled within the range of 90 % -99 %. In order to further optimize the material properties, a small amount of functional oxides, such as titanium dioxide ( TiO 2 ), silica ( SiO 2 ), zirconia ( ZrO 2 ), etc., will be added to the basic formula. Taking zirconia as an example, its phase transformation toughening effect can significantly improve the impact toughness of the ceramic sheet and effectively reduce the fracture risk of the material under dynamic load. Titanium dioxide enhances the wear resistance and surface hardness of the ceramic sheet by refining the grain and solid solution strengthening mechanism.

2.Preparation technology

The preparation of alumina ceramic sheet involves multiple precision processes, including four key links : raw material preparation, body forming, high temperature sintering and post-processing.

( 1 ) Preparation of raw materials

The high purity alumina powder was used as the base material, and the functional additives were accurately matched according to the preset formula. The mechanical mixing was carried out by high-energy ball milling equipment to ensure that the components reached nano-level uniform dispersion. The mixture was subjected to spray drying granulation to prepare spherical particles with good fluidity and reasonable particle size distribution, which provided high-quality raw materials for the subsequent molding process.

( 2 ) Green body forming

According to the shape and performance requirements of the product, different molding processes can be selected : dry pressing is suitable for the preparation of ceramic sheets with large size and simple structure, and the material densification is realized by mold under high pressure ; the isostatic pressing technology uses the uniform pressure transmission characteristics of the fluid medium to prepare a high-performance body with uniform density and low internal stress. The injection molding process meets the manufacturing needs of special-shaped ceramic products by virtue of its complex structure forming ability.

( 3 ) High temperature sintering

High temperature sintering is the core process to determine the performance of ceramic sheet. The green body was placed in a high temperature sintering furnace. Under the set temperature curve, the solid phase diffusion and recrystallization reaction occurred between the ceramic particles, and the densification of the green body was realized. The precise control of sintering temperature and holding time is very important. Too high temperature or too long holding time may lead to abnormal grain growth, thermal stress concentration and other defects, affecting product performance.

( 4 ) Post-processing

The sintered ceramic sheets need to be processed by precision machinery, including high-precision cutting, grinding and polishing to meet the stringent dimensional accuracy and surface roughness requirements in engineering applications.

3.Performance characteristics

( 1 ) High hardness

( 2 ) High wear resistance

( 3 ) Chemical stability

( 4 ) High temperature stability

( 5 ) Low density

( 6 ) Good insulation performance

4.Industrial applications

( 1 ) Electric power industry

In the pulverized coal conveying system, fan components and desulfurization equipment of coal-fired power plants, alumina wear-resistant ceramic sheets effectively inhibit material erosion and chemical corrosion through surface protection technology, reduce equipment maintenance costs, and improve system operation reliability.

( 2 ) Iron and steel industry

It is used in ore conveying pipeline, blast furnace burden distribution system and sintering equipment. The ceramic sheet can significantly reduce the friction loss of materials, improve the operation efficiency of equipment, and ensure the continuity of steel production process.

( 3 ) Mining industry

In the mineral processing equipment, crushing machinery and material conveying device, the alumina wear-resistant ceramic sheet ensures the stable operation of the equipment under high load conditions and reduces the downtime maintenance frequency by virtue of its excellent impact and wear resistance.

( 4 ) Chemical industry

As a corrosion-resistant lining material, aluminium oxide wear-resistant ceramic sheets are widely used in chemical reactors, pipelines, valves and other equipment to effectively protect chemical medium erosion and improve the safety and stability of chemical production processes.

In summary, alumina wear-resistant ceramic sheets play an indispensable role in the modern industrial field due to their unique material system, advanced preparation process and excellent performance advantages. With the continuous innovation of material science and engineering technology, the performance of the material will be continuously optimized and the application field will be further expanded.