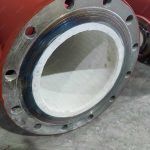

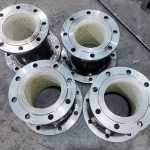

In industrial production systems, selecting the right piping system is a core component of cost control and efficiency optimization. Sitomat Wear-Resistant Ceramic Pipes, engineered for superior performance, have become a critical technology choice for industries aiming to optimize capital allocation and operational outcomes.

The relationship between pipeline service life and cost

From a life cycle management perspective, these pipes offer a significant durability advantage. Field tests show their service life exceeds traditional wear-resistant pipes by over 600%—that’s six times longer. This longevity drastically reduces annual planned downtime for replacements—a critical benefit in continuous production environments where shutdowns stall output and incur hidden costs like labor reallocation and process restart inefficiencies. By extending service cycles, Sitomat pipes keep downtime losses well below industry averages, boosting production line efficiency and delivering sustainable capacity gains. Longer life also means fewer replacements, cutting total lifecycle maintenance costs at their root.

Why wear-resistant ceramic pipes can help your factory improve efficiency and reduce costs?

A cost-benefit analysis quantifies this economic edge clearly: Over a five-year period, traditional wear-resistant steel pipes (1-year lifespan, $100k pipe + $20k installation per cycle) require five replacements, totaling $600k in direct costs. In contrast, Sitomat Ceramic Pipes (5-year lifespan, $300k initial cost + $30k installation) require just one upfront investment, with total lifecycle costs capped at $330k. Factoring in downtime-related production losses (based on industry-average shutdown costs) and labor management expenses, the total savings exceed $400k. This comparison proves that while upfront costs are slightly higher, long-term savings from fewer replacements and minimal downtime make Sitomat pipes far more economical.

Additionally, advanced material surface treatments and structural design reduce maintenance needs by 60% compared to traditional solutions, cutting repair costs by 45%. In industrial settings, the human labor, spare parts, and time required for equipment maintenance are often underestimated. Sitomat pipes free up maintenance resources to focus on core production by minimizing inspections and repairs, delivering dual benefits of direct cost reduction and indirect efficiency gains. This combination of cost control and reliability has become a key competitive advantage for businesses aiming to strengthen their market position.

In summary, Sitomat Wear-Resistant Ceramic Pipes represent a high-performance, long-life, low-maintenance piping solution that systematically optimizes time, material, and opportunity costs in production. For modern industries seeking lean manufacturing and value-driven outcomes, they deliver a scientifically proven engineering solution that aligns technology with bottom-line results.